Part Ways with PCBs Through NASA’s Activated Metal Treatment System

Polychlorinated biphenyls (PCBs) are chemicals or industrial products that have been banned in the United States due to their danger to both the environment and human health.

Before 1979, PCBs were used in electrical insulators, capacitors, electric appliances, and even on dirt roads, but the real problem surfaced in their ability to contaminate air, water, and soil during manufacturing or use.

Even though PCBs are no longer being manufactured, it is critical for experts to use caution when removing or disposing of these chemicals from contaminated sites.

Fortunately, with help from the University of Central Florida (UCF), Anchor QEA implemented a series of tests using an Activated Metal Treatment System (AMTS), developed and patented by the National Aeronautics and Space Administration (NASA), to evaluate the effectiveness of its dechlorination capabilities that allow for safe and non-hazardous PCB disposal.

How Does AMTS Work?

AMTS is a paste-like formulation that can be applied to different types of building materials to extract PCBs and break them down into benign byproducts. The resulting building material can then be safely reused or recycled, with no additional PCB-specific treatment necessary.

AMTS technology has been used to successfully extract PCBs from painted metal—a non-porous surface—at NASA facilities and other U.S. Department of Defense installations. The UCF developed a modified AMTS formula that is even more effective in extracting and destroying PCBs from non‑porous surfaces (e.g., metal) in addition to porous surfaces (e.g., concrete).

Testing AMTS on Porous and Non-Porous Surfaces

When Anchor QEA conducted pre-design investigations on a site where demolition was scheduled in 2022, a source of PCBs in paint found on both concrete walls and metal pipes proved the perfect opportunity to evaluate the efficacy of NASA’s AMTS technology.

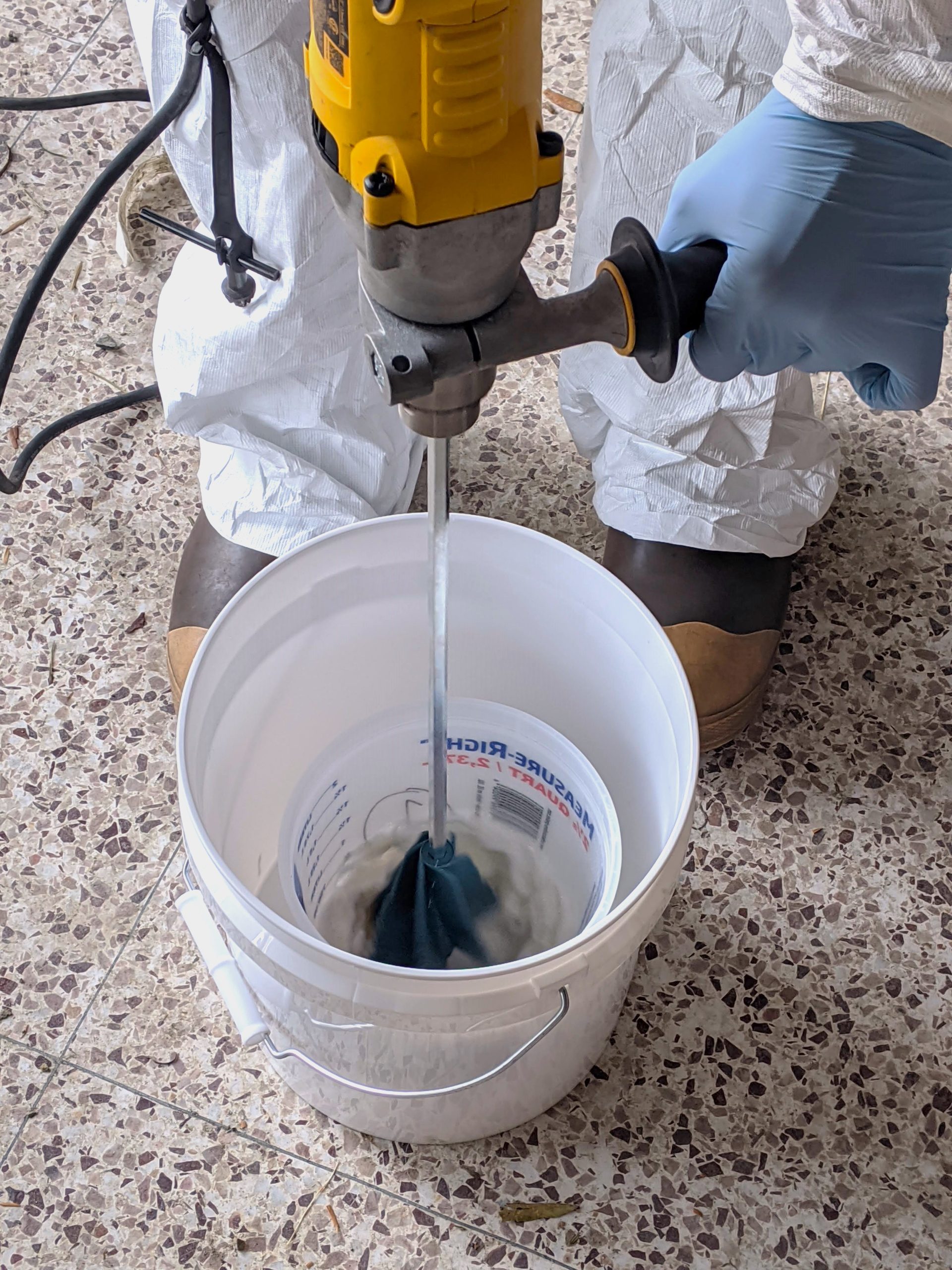

Anchor QEA procured the raw materials needed to prepare the paste, using the NASA-patented reagents together with the procedures and weight percentages provided by UCF. Testing at the site helped assess different application methods of UCF’s AMTS formula for both porous and non-porous PCB-contaminated building materials, revealing the optimal duration and number of applications needed to achieve the site cleanup level (1 ppm) or reduce concentrations below hazardous waste levels (50 ppm).

AMTS Takeaways

Results showed that application of AMTS reduced PCB concentrations on painted metal (a non‑porous surface) by an average of 94% and reduced PCB concentrations on painted concrete (a porous surface) by an average of 12%.

While the AMTS paste was able to reduce PCB concentrations for both material types tested, concentrations at the end of the program were not low enough for non-hazardous disposal or below the site cleanup level for beneficial reuse on site, and as such, was managed as PCB bulk product waste during demolition for this site.

As the PCB breakdown process can vary greatly depending on the chemicals’ makeup and location, these results need not be dismissed. AMTS technology, with customized application, has the potential to not only eliminate hazardous PCB concentrations but reduce extraneous disposal costs and allow for on-site reuse and recycling, factors that make this treatment a solution worth trying or at least a matter worth looking into further.