How CFD Modeling Can Help Solve the Aging Dam Infrastructure Dilemma

In June 2021, Wisconsin-based FreshWater Engineering joined with Anchor QEA to expand their high-quality water resources engineering services to clients nationwide. Founded in 2014 by Laura Rozumalski, FreshWater specializes in waterway restoration, sustainable stormwater management, and coastal engineering. Learn more about FreshWater Engineering joining Anchor QEA here.

Across the United States, dams store water for drinking and irrigation, to control flooding, and to generate hydroelectric power. Hydropower is one of the most impactful green energy technologies, producing 17% of the total power generated globally. However, the average age of dams in the United States is 56 years, and 14% of the nation’s 91,000 dams are considered to have high hazard potential, according to the American Society of Civil Engineers. Complex issues can often arise at dams due to rapid or unforeseen deterioration, high flows, sediment transport, and public safety risks.

Owners and operators can improve a dam’s operation with the aid of computational fluid dynamics (CFD) modeling, a great tool to analyze complex hydraulics with changing site conditions. CFD uses numerical analysis, fluid mechanics, and computer science to simulate how a liquid stream flows and how those flows affect the surrounding environment. It is a powerful tool for optimizing the design of dams, spillways, stilling basins, weirs, and other structures.

Design and performance analysis are crucial for ensuring the economical and efficient functioning of the hydropower dams.

Hydrodynamic Modeling: Solving Dams’ Most Challenging Problems

A dam’s capacity to generate energy depends on its available flow. CFD model evaluations of the height from which water falls to the turbines, the suitability of gates that adjust the mass flow rate, the turbine configuration, and the water pressures are critical to analyzing and optimizing dams and hydropower plants to increase their efficiency. With CFD modeling, the environment is virtualized and simplified into a digital model that includes numerical representations of the material elements and methods of solving physical equations that simulate the motion of the flow.

A CFD model can factor into dam spillway basin design control structures, energy dissipation, fish passage and design, and dam break.

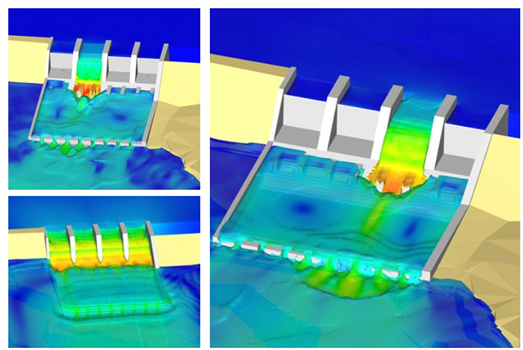

This type of hydrodynamic modeling accurately and efficiently simulates flows in the natural and built environments. With FLOW-3D, an industry-leading CFD software package, we can simulate and visualize complex geometries and fluid flow conditions. It eliminates the assumptions and uncertainties of other models, enabling users to unlock insights not available through other analytic methods.

Analyzing Flow Patterns to Find Solutions at a High Hazard Spillway

Typically located on or adjacent to a dam, spillways are essential to the dam’s continued safety and hydraulic operations. Spillways allow surplus water or floodwaters to pass in a manner that protects the dam’s structural integrity. Proper operation of a dam in an emergency may depend on the ability of its outlet works and gated spillways to make releases.

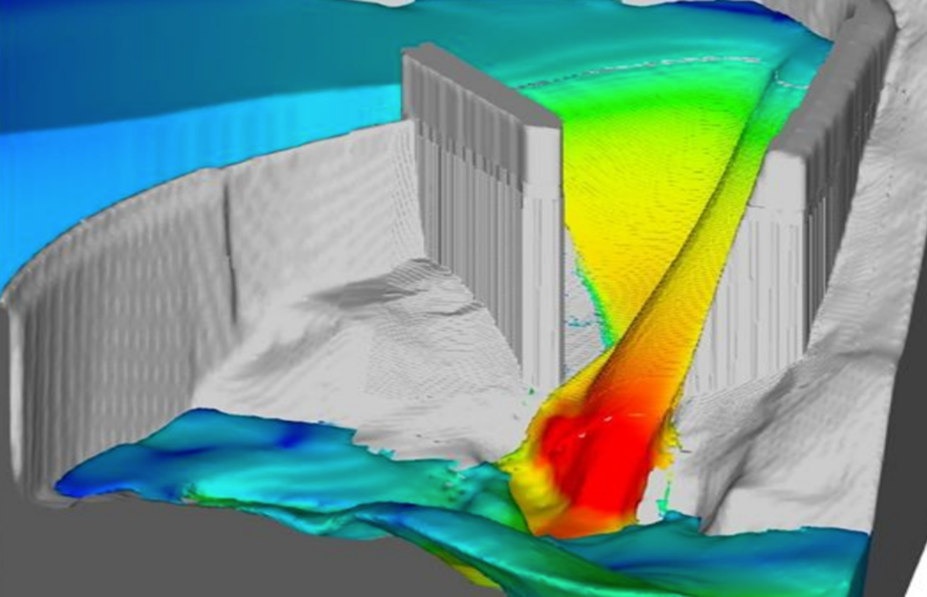

When the spillway at a high hazard dam was nearing the end of its service and needed to be replaced for the dam to continue operating, the FreshWater team used CFD modeling to evaluate flow parameters and assess, under various flow rates, designs for several potential replacements.

FLOW-3D can simulate near-field and far-field process dynamics in riverine environments to evaluate various flow rates.

The model provided flow velocities, shear stresses, and pressures along the length of the spillway and surrounding terrain. This analysis discovered an open vortex that formed under certain flow conditions. As a result, the design engineers could better estimate the required spillway wall height, evaluate the risk of any spillway damage, and visualize flow patterns.

Simulations to Manage Changing Water Levels at a Hydroelectric Dam

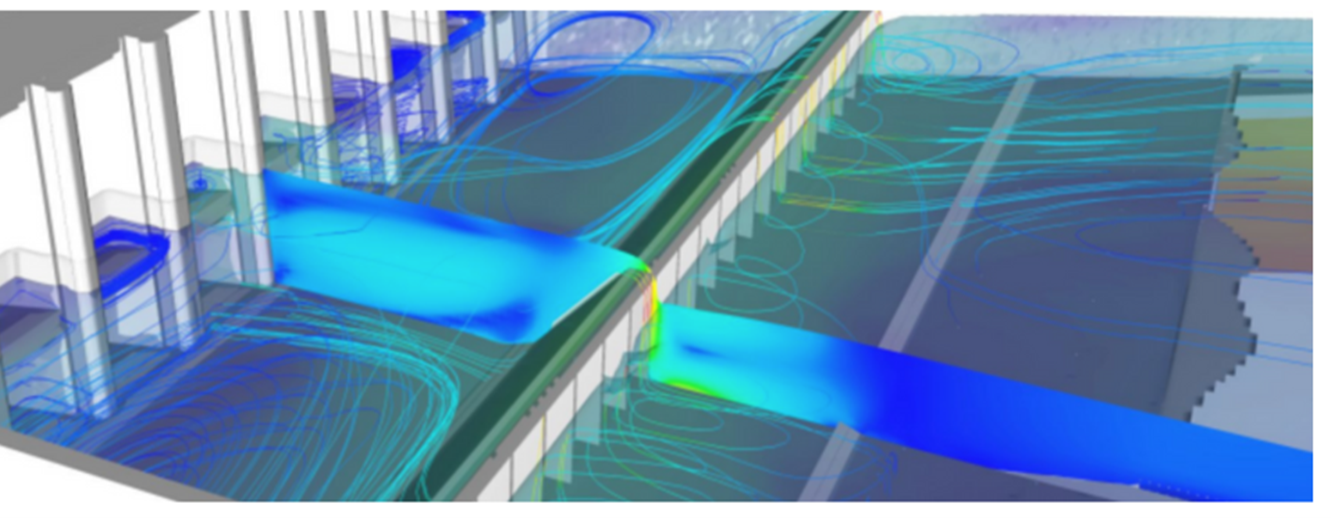

A hydroelectric dam was facing decreased water levels downstream, leading to implications on the effectiveness of the generator bays. After conducting a field investigation, our team simulated design alternatives for a tailrace weir, the area downstream of the dam, to maintain higher water surface elevations that would permit uninterrupted generation at the site. Having collected bathymetric and topographic data, we were able to develop a CFD model to better analyze, visualize, and interpret flow velocities and hydrodynamic forces at the project site.

CFD can assess spatial and temporal variations of flow velocity and energy imperative for water levels and fish passage structure designs.

With the CFD model, we effectively analyzed a wide range of flow events— from a single generating bay operating at full capacity to all generators and the regulating bay operating at maximum discharge—and their effects on the tailrace weir. The CFD model also helped inform dam owners about the proposed design strategies, quickly visualize flow patterns, and efficiently validate potential solutions.

Ultimately, through CFD modeling, project teams are able to effectively simulate any process dynamics within riverine environments, better understand and communicate flow events, and have a positive impact on the dams and their surrounding environment.